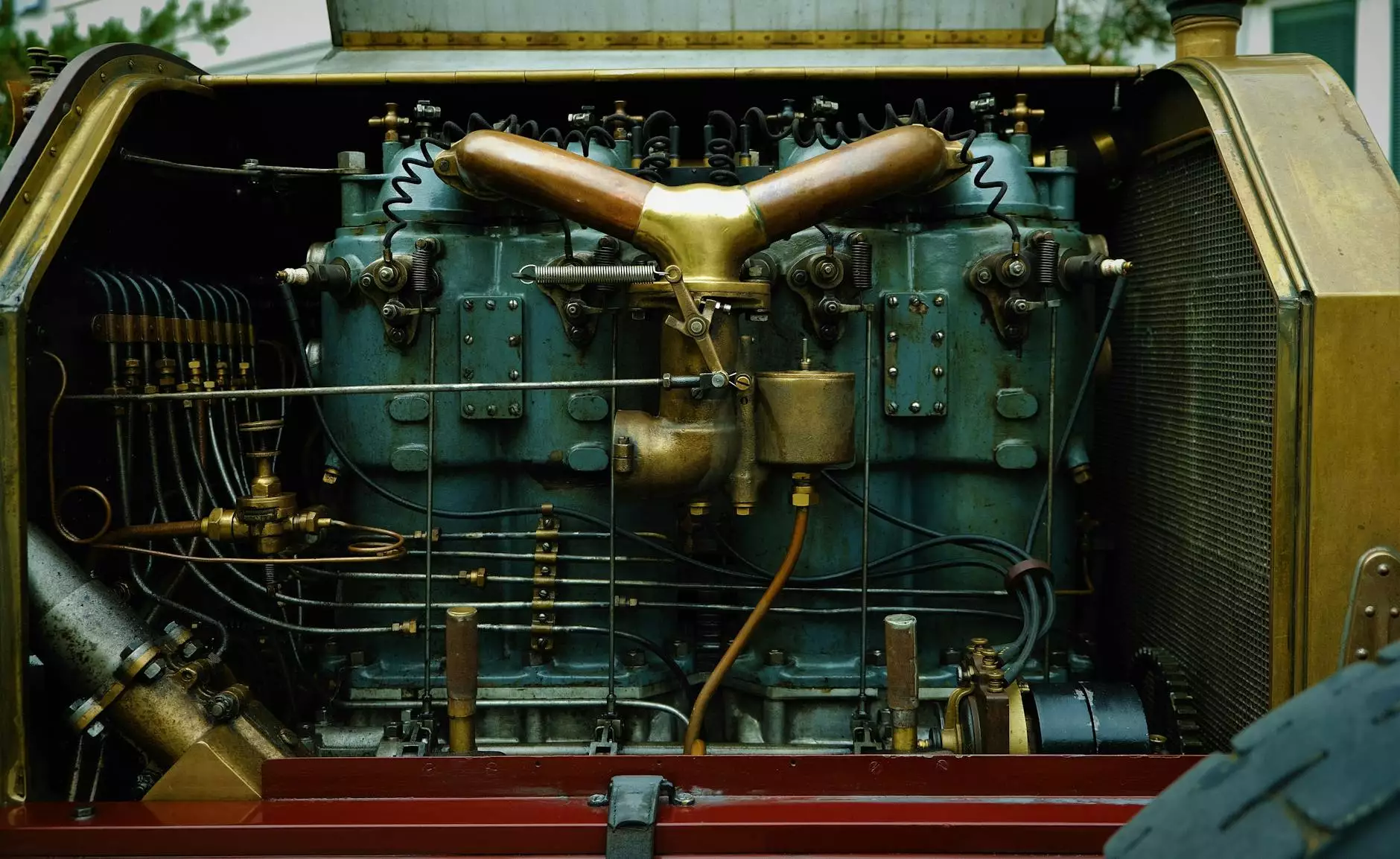

The Vital Role of the Oil Pump Engine in Diesel Engines

In the world of diesel engines, one component stands out in its importance: the oil pump engine. This critical engine part enables smooth operation, enhances performance, and guarantees the longevity of the engine. Understanding the intricacies of oil pump engines and their functionalities can greatly benefit those involved in the maintenance and operation of diesel engines.

What is an Oil Pump Engine?

The oil pump engine is a mechanical device used to circulate engine oil throughout the engine's internal components. Its primary function is to deliver oil to the engine, ensuring that parts are lubricated, allowing for reduced friction, efficient operation, and the prevention of overheating.

How Does an Oil Pump Work?

The functioning of an oil pump engine can be broken down into a few key steps:

- The oil is drawn from the oil pan through a pickup tube as the oil pump begins its operation.

- The pump pressurizes the oil, pushing it through various oil passages.

- The pressurized oil lubricates essential components such as bearings, camshafts, and pistons.

- Finally, the oil returns to the oil pan, and the cycle repeats.

Types of Oil Pumps Used in Diesel Engines

There are primarily two types of oil pumps used in diesel engines:

1. Gear Oil Pump

The gear oil pump consists of two gears that mesh together to pump oil. As the gears turn, they create a void that pulls oil into the pump, which is then forced out under pressure. This type of pump is commonly found in diesel engines due to its efficiency and reliability.

2. Vane Oil Pump

The vane oil pump uses sliding vanes within a rotor to create a pumping action. It is known for its ability to provide a consistent flow rate and is often used in high-performance diesel engines. However, its complexity can lead to higher maintenance requirements.

Importance of Oil Pumps in Diesel Engines

The oil pump engine plays a pivotal role in the overall functionality and reliability of diesel engines. Here are some key reasons why oil pumps are crucial:

- Lubrication: Proper lubrication reduces friction between moving parts, which minimizes wear and tear.

- Heat Reduction: Circulating oil absorbs heat generated by the engine, preventing overheating.

- Contaminant Removal: The oil pump helps in collecting impurities and contaminants within the engine, which can be filtered out.

- Efficiency: An efficient oil pump ensures that oil reaches all necessary components quickly, improving overall engine performance.

Signs of a Failing Oil Pump Engine

A malfunctioning oil pump engine can lead to severe engine damage. Here are some warning signs to look out for:

- Oil Pressure Warning Light: This dashboard indicator signals that oil pressure is lower than normal, suggesting a problem with the oil pump.

- Unusual Noises: Listen for grinding or knocking noises from the engine, which may indicate insufficient oil lubrication.

- Overheating: If the engine temperature rises beyond normal levels, it could be a sign of inadequate oil circulation.

- Low Oil Levels: Continuously low oil levels with no visible leaks may point to a failing oil pump.

Maintenance Tips for Oil Pump Engines

Keeping your oil pump engine in top condition is vital for your diesel engine's longevity. Here are some maintenance recommendations:

- Regular Oil Changes: Follow the manufacturer’s guidelines for oil change intervals to ensure optimal performance.

- Inspect Oil Levels: Frequently check oil levels to avoid running the engine with insufficient lubrication.

- Use Quality Oil: Invest in high-quality oil that meets specifications outlined by your engine manufacturer.

- Monitor Oil Pressure: Keep an eye on the oil pressure gauge. Any significant drops should be investigated immediately.

- Replace the Oil Pump When Necessary: If you notice any symptoms of failure, consider replacing the oil pump to avoid catastrophic engine damage.

Choosing the Right Oil Pump for Your Diesel Engine

When it comes to selecting an oil pump engine, compatibility and performance are key factors. Factors to consider include:

- Engine Type: Ensure the oil pump is designed for the specific diesel engine model you have.

- Flow Rate and Pressure: Assess the required flow rate and oil pressure for optimal performance.

- Durability: Choose pumps made from high-quality materials that can withstand the demands of your engine.

- Repairs and Parts Availability: Check for availability of replacement parts for easier maintenance in the future.

Conclusion

The significance of the oil pump engine in diesel engines cannot be overstated. It is essential for ensuring that critical engine components are well-lubricated and protected from wear and heat. By understanding how oil pumps work, recognizing potential issues, and adhering to proper maintenance practices, diesel engine owners and operators can secure optimal engine performance and prolong the lifespan of their machinery.

Contact Us

If you're in need of Diesel Engine Parts or are looking for trusted Spare Parts Suppliers, look no further than client-diesel.com. Our extensive inventory and expert team are ready to assist you with all your diesel engine needs.